Model:dry cut

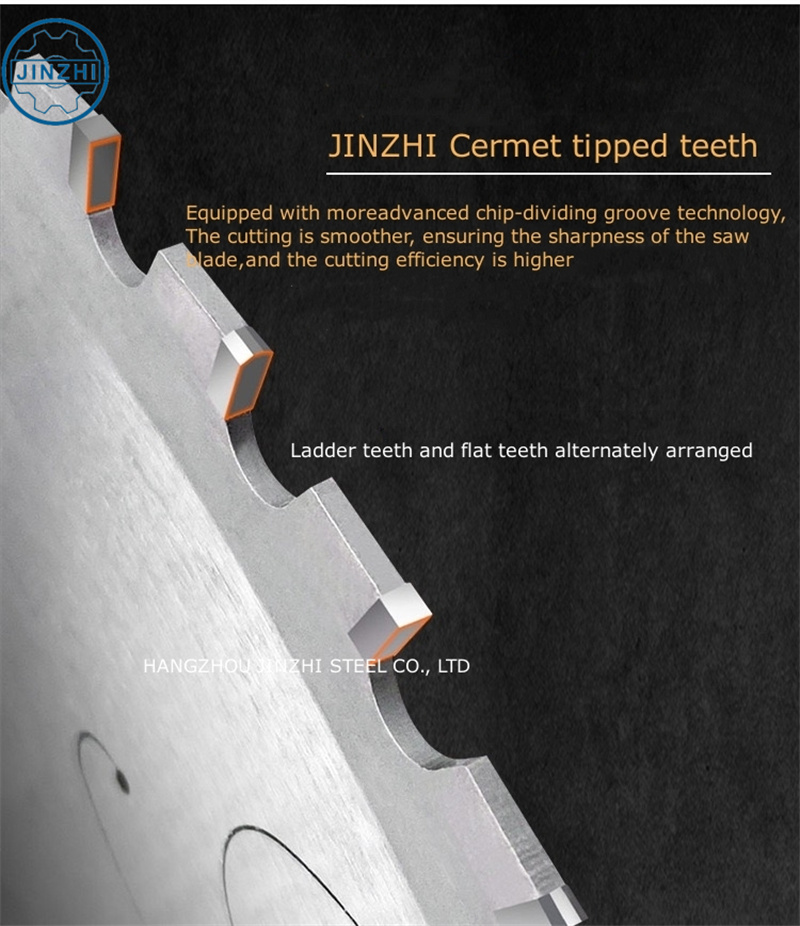

Type:Cermet tipped

Coating: tooth coated

Diameter to: 710mm

Thickness to :50mm

Product Description

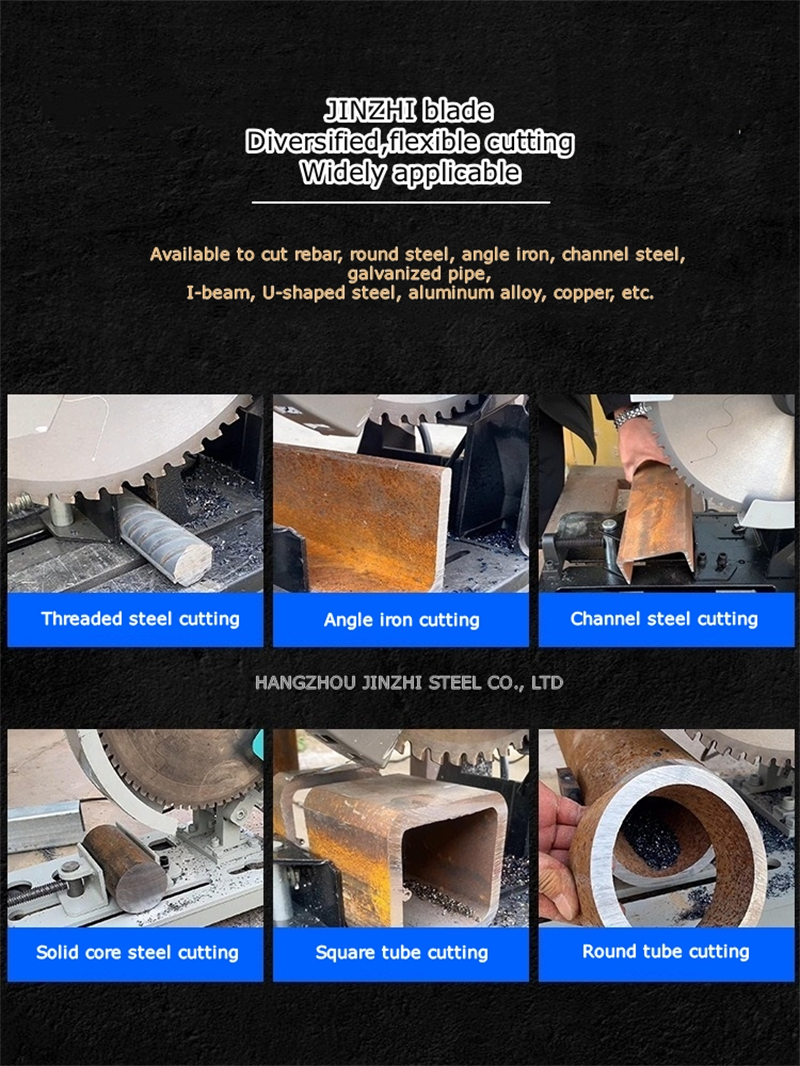

Product Name: Cermet Circular Saw Dry Cut for Iron

Keywords: Cermet circular saw, dry cut, iron

This Cermet Circular Saw Dry Cut for Iron is a high-quality cutting tool designed specifically for cutting

iron materials.

With its durable cermet construction, this circular saw delivers precise and efficient cutting results.

The dry cut feature eliminates the need for coolant, making it a convenient and cost-effective solution

for your cutting needs.

Whether you are working in a fabrication shop or a manufacturing facility, this Cermet Circular Saw is a

reliable tool that will enhance your productivity and accuracy.

Invest in this top-of-the-line cutting tool and experience the difference in performance and durability.

Diameter(mm) | Width(mm) | Hole(mm) | Teeth (mm) |

185 | 1.8 | 25.4 | 32 |

205 | 1.8 | 25.4 | 32 |

255 | 2.0 | 25.4 | 48/54/60 |

205 | 2.0 | 25.4 | 48/54/60/80 |

355 | 2.2/2.4 | 25.4 | 66/72/80 |

405 | 3.2 | 32 | 72 |

450 | 2.8 | 32 | 84 |

Advantages

1.Smooth cut surface

2.Not easy to lose teeth

3.fine cutting

4.Widen blade

5.Sharp and wear-resistant

6.Suitable for dry cutting

Application

Packing

OEM&ODM

Provide CUSTOMIZED SERVICES!!

OEM & ODM!

Customized products according to customer's requirements!

Color, Material, Logo, Package, Size, Craftsmanship and so on...

Certificate

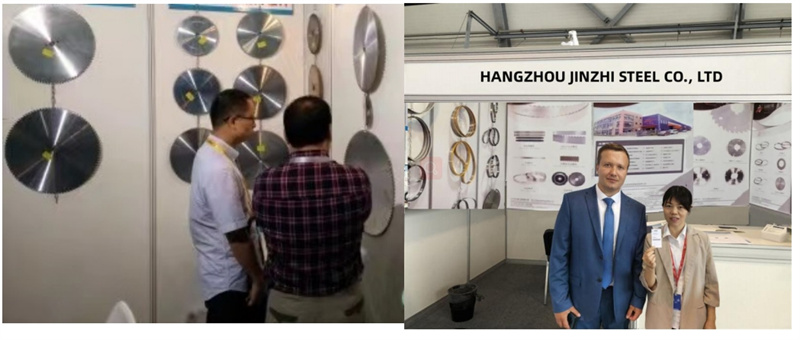

Exhibition Photos

FAQ

Q1. What is your MOQ?

A: sample order is accepted,always 5pcs for MOQ.

Q2. What is your delivery time?

A: 10-15 days.

Q3. Can you produce according to samples or drawings?

A: Yes, we can produce by your samples or technical drawings.

Q4. How do you guarantee your production quality?

A: We take delivery test with professional Inspection equipment before shipment.

Q5. What countries have you exported?

A: Our business expanded to all over the world.

INSTRUCTION FOR USE

1. Please read the instruction manual in detail, correctly select the type, grade,

and specification of the saw blade according to the cutting material and cutting

requirements, and perform standard installation and operation.

2. The saw teeth have high hardness and the tooth tips are fragile.

The base body has been heat treated and leveled. Do not knock, press,

or impact during installation and storage. The plastic tooth guard can only

be removed after the saw blade is installed.

3. The angle and material of the saw teeth are designed and selected strictly

according to the cutting materials. Please choose saw blades of different types,

grades, and specifications according to different uses and types of materials to

be cut, otherwise it is easy to cause chipping and broken teeth. and other phenomena

may damage the saw blade.

4. The dynamic balancing performance of the saw blade has strict requirements.

It is strictly prohibited to change the size of the mounting hole of the saw blade

and the geometry of the saw blade.

5. Do not install the saw blade reversely for cutting. Do not perform cutting operations

when the saw blade does not reach the normal speed. The speed is not allowed to be

too high or too low during use.

6. Pay attention to controlling the feeding speed, otherwise it will seriously affect the

cutting, and even cause accidents such as tooth chipping or broken teeth.

7. The saw blade will wear out after being used for a long time and should be sharpened

and sharpened in time before it can be used again.

8. When the saw blade has chipped or broken teeth or cracks appear in the saw blade base,

a new saw must be replaced in time. The footprint accuracy has a great impact on the use effect.

Check and adjust the saw blade before installing it.

Contact: John

Phone: 0086-13958112242

E-mail: karen@jinzhi-steel.com

Whatsapp:0086-13958112242

Add: No.18 Kangjing RD, Gongshu district,Hangzhou,Zhejiang Province,China.

We chat