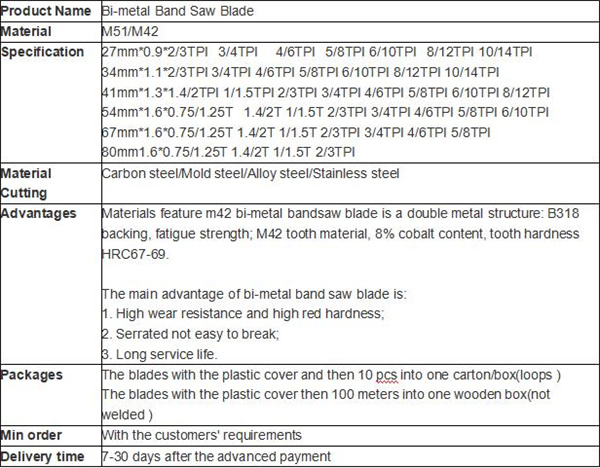

Name:M42 Bi-metal Metal Cutting Band Saw Blade.

Size:27*0.9, 27mmx0.9x3/4TPI.

Edge Height:0.315in(8mm), 0.472in(12mm).

Cutting material:Metal Stainless Steel Carbon Steel Aluminum.

Process Type:HOT PRESS, Cold PRESS.

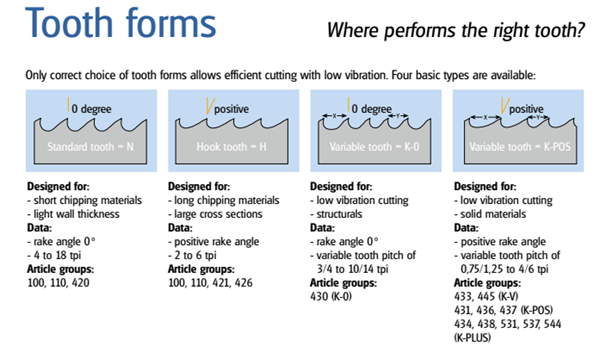

Standard tooth-N

Features:Zero front angle,mostly used for tooth of 4/6 and below .

Benefits:1.Good impact resistance.

2. Chip removal ability

Application:Mainly suitable for sawing cutting small pipes

Curved back tooth form

Features:Special tooth geometry is resistant against vibrations and heavy irregular mechanical strain arising.

Benefits:1.A large chip-containing space

2. Good cutting performance and chip -removing ability

3.Good impact resistance.

4. Best cutting performance in high vibration.

Application:Widely used in the cutting of pipes,profiles and bundle materials,carbon steel to stainless steel,tool steel other difficult to cut materials.

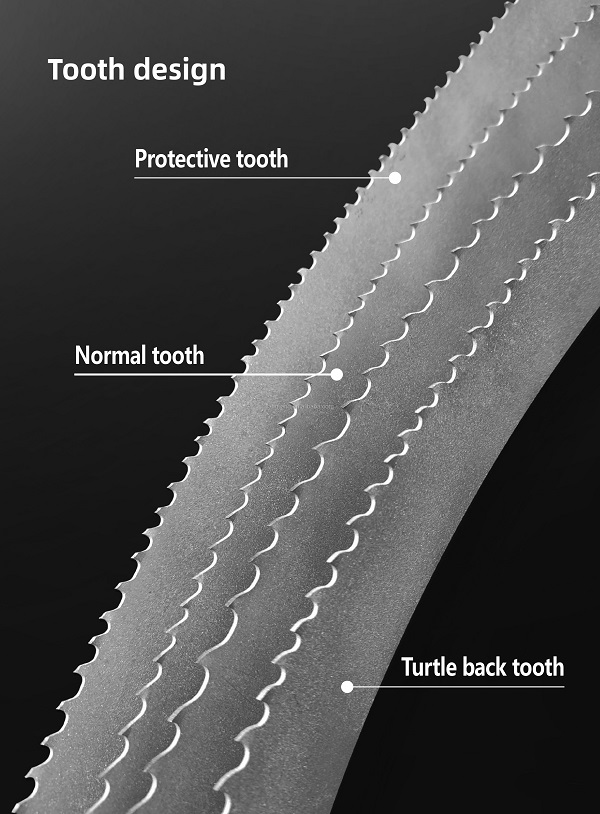

Protective tooth form

Features: Deep tooth groove design,with good chip capacity

Benefits:1.Good tensile resistance.

2. Chip capacity

Application: Mainly used for sawing large solid materials that are easy to broken teeth.

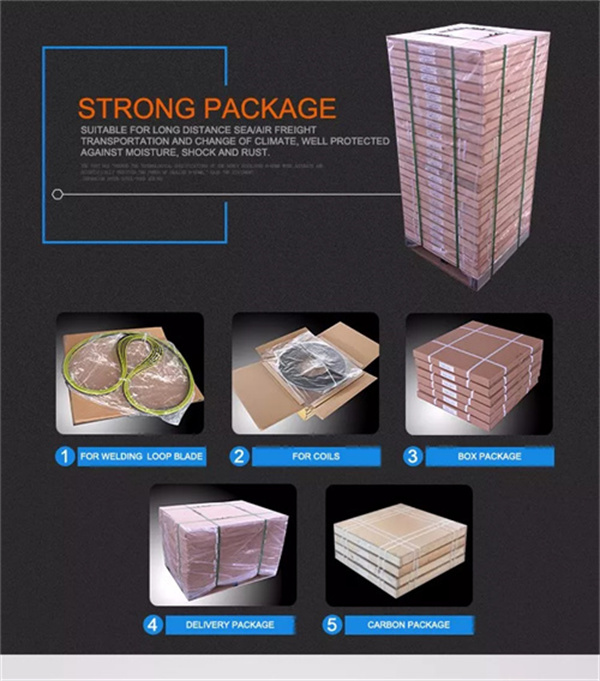

Packing:

Base on customer's requirements

We can make the band saw blades in coil blades or in weld loop.

2.The length for coil or piece is according to your requirements.

3.Saw teeth is sealed-free ,waterproof, oxidation-proof, anti-transportation impact, and each saw tooth is well

protected.

4.The coil baldes packaging:

The length per coil is as below (acture length may have little fluctuation)

1 coil 100 meter for 27mm,34mm

1 coil 100 meter for 41mm

1 coil 90- 100 meter for 54mm,67mm

Per 1 coil into a carton box ,then several cartons in wood case.

5. The weld loop packaging: 5 PCS/carton or10 PC/carton or 20 PCS/ carton

6. International standard packing:

Best stainless steel wing nut anchor for construction fastener bags+cartons+pallets according to customer's

requirements

7.We like to accept your packing ,too.

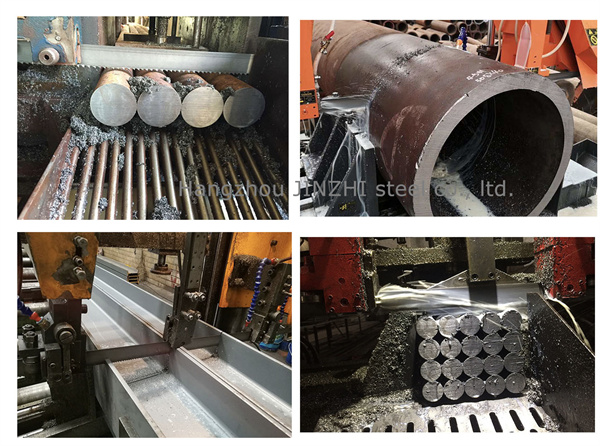

Factory production

Application

Real photo

In order to better use our products, we should make the choice of teeth per pitch,and relevant questions and answers are as follows:

Q1. What is the appropriate tooth pitch when cutting a single layer of 10 tubes ,each of them with a 20mm outer

diameter and thickness of 1mm?

A. Fine teeth such as 8/12 or 10/14 is recommended when cutting thin pipe wall.

Q2. What is the appropriate tooth pitch when cutting a round bar of 100mm outer diameter ,whose materials

might be DIN C45E,ST33,ST52-3?

A. 3/4 pitch is recommended.

Q3. What is the appropriate tooth pitch when cutting a stainless tube of 120mm outer diameter and 1.5mm

thickness.

A. 8/12 pitch is recommended

Q4. What is the appropriate tooth pitch when cutting a round bar 45Cr ,with its diameter of 600mm?

A. 1/1.5 pitch is recommended when the material is of such big size

Q5. What is the appropriate tooth pitch when cutting bearing steel of various size from 20-150mm?

A. Different pitches shall be adopted when cutting materials of different sizes .

For sizes of 20-50mm,4/6 pitch is recommended ,

For 70-150mm,3/4 pitch

3/4 tooth pitch is mainly used for cutting steel of 50-200 diameter and cutting of thick wall pipe

4/6P tooth pitch is product impact resistant ,mainly used for cutting of thin wall tube and cutting profiles.

Contact: John

Phone: 0086-13958112242

E-mail: karen@jinzhi-steel.com

Whatsapp:0086-13958112242

Add: No.18 Kangjing RD, Gongshu district,Hangzhou,Zhejiang Province,China.

We chat