Description

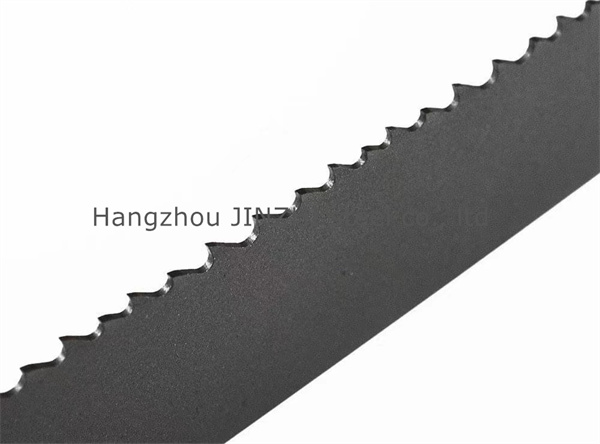

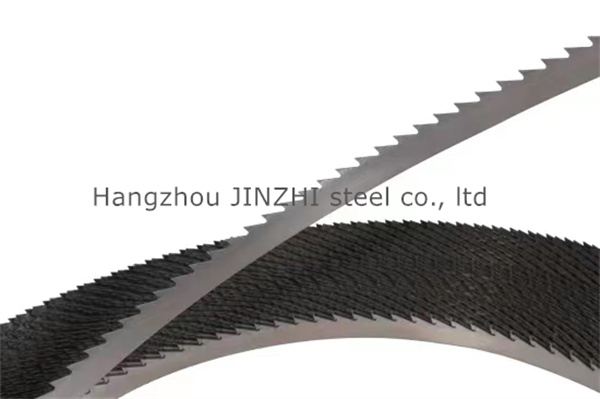

The invention relates to a bimetal saw blade, in which at least the tooth tips are made of a hard metal and the carrier tape consist of a comparatively tough steel and takes the priority of the German patent application 102 02 770.6-14.

1.Saw bands, which also include saw blades in the present case, must have high dimensional stability of their cutting edges as well as high wear resistance and be able to cope with the high stress caused by pressure, bending and shearing forces, even at the not inconsiderable temperatures that result from the friction between Saw band and material to be cut result. This applies in particular to saw bands that rotate at high speed and subject to severe bending when deflected.

Since it is difficult to combine the required properties in a single material, there are Bimetal saw bands nowadays usually consist of a relatively tough carrier band with high bending strength and also a band-shaped cutting part made of high-speed steel or cold-work steel with low Toughness but high wear resistance. The cutting band is so wide that at least the tooth peaks of the saw band or blade or the cutting teeth can be worked out as a whole.

It is known that the carrier tape and the cutting tape by laser or electron beam welding without to connect additional material to each other.

In practice it has been shown that under the influence of the welding heat, there is often a distortion of the teeth or the tooth tips, so that they no longer have the intended angular position in relation to the saw band .

2. Taking the saw blade level and consequently being subject to much greater wear. As a cause for this, local concentration differences in the area of the weld seam could be determined. Such concentration differences and in particular when welding two differently composed Materials inevitably resulting concentration gradient transverse to the weld often lead to residual stresses and thus to an impairment of the service life.

3. EP 0 569 346 A1 also already includes a bimetal saw band or blade made from a steel carrier band

0.20 to 0.40% carbon, 2.5 to 5.0% chromium, 2.0 to 3.0% molybdenum, 0.03 to 0.4% vanadium and as a grain refiner total less than 0.01% Niobium and titanium on the one hand and a cutting band made of high-speed steel with 0.65 to 1.8% carbon, 3.0 to 6.0% chromium, 4.0 to 12.0% molybdenum and 0.5 to 5.0% vanadium.

A special feature of this saw band is the simultaneous presence of chromium, vanadium and molybdenum in it both materials and the limitation of the total content of niobium and titanium in the carrier strip to a maximum of 0.01% from the point of view of sufficient fatigue strength. Included to improve weldability

both materials also contain aluminium, namely up to 2.0% in the cutting part and up to 0.15% in the carrier strip. EP-0 569349 A1 also describes a similar bimetal saw blade.

Also known is the use of sintered hard metal as a material for the tooth tips of a saw band.

Such cemented carbides consist essentially of tungsten carbide in a bedding compound of 4 to 15% cobalt

Binding metal, optionally with small amounts of titanium and tantalum carbide. The use of carbide tips

However, there is a risk of increased brittleness and susceptibility to fracture in the area of the fused joint between the carbide tooth tips and the steel carrier strip. To counteract this and a higher

To ensure toughness or better pressure and impact sensitivity, it is advisable to use hard metals, which have a higher hardness and toughness due to their fine-grained structure. The fine-grained structure

is lost, however, because it is in the fusion bonding of the cutting teeth with the carrier tape under the influence of

Heat from welding or during operation under the influence of the friction heat occurring during high-speed sawing leads to spontaneous grain growth through recrystallization. The grain growth is all the stronger,

the smaller the grain size. Islands with large tungsten carbide crystals form in the microstructure, which under mechanical and/or dynamic loads, i.e. high cutting pressures and cutting speeds or vibrations, promote the formation of fractures. This grain growth is also associated with the emergence of brittle phases and

internal stresses in the melting zone on both sides of the hard metal/carrier strip interface.

Contact: John

Phone: 0086-13588010030

E-mail: karen@jinzhi-steel.com

Whatsapp:0086-13588010030

Add: No.18 Kangjing RD, Gongshu district,Hangzhou,Zhejiang Province,China.

We chat